Fencing gates

Supreme double-leaf gates

Double-leaf gates and wickets are manufactured in the same heights as Infinity segments, while their width is specified by the Customer according to individual needs. These products have been designed so as to stylistically match the appearance of the Infinity palisade fence as its natural complement. Gates are operated manually or automatically by means of electromechanical actuators and remote control.

Width range

2,0 – 5,0 m

Height range

1,09 -1,685 m

filling profile

70 mm

filling spacing

15 mm

Technical parameters

| Height of gates and wickets | Clearance width of gates and wickets |

| 1,09 / 1,175 / 1,26 / 1,345 / 1,43 / 1,515 / 1,60 / 1,685 m | gates from 2.0 to 5.0 m, wickets from 1.0 to 1.5 m |

| Structure of gates and wickets | Filling cross-section |

| Closed 70×40 mm profile | Closed 70×20 mm profile |

| Filling spacing | Cross-sections of gate and wicket posts |

| Spacing of profiles – 15 mm | 80×80 / 100×100 / 120×120 mm |

| Standard gate equipment | Standard wicket equipment |

| Hinges, bottom bolt lock, hasps | Hinges, key-lock and handle |

| Gate equipment options | Wicket equipment options |

| reinforcement for automation system | electric strike with handle, intercom |

| Gate operation | Wicket operation |

| manual or automatic (actuators) | manual or mechanical self-closer |

Options

- Gate in set with wicket – if the wicket is to be directly adjacent to the gate, we can make these elements as a single structure with a common post. It is recommended for the wicket’s leaf not to open onto the gate’s leaf, but in the opposite direction.

- Gate with wicket function – one of the leafs is equipped with a lock and handle, and this also makes it possible to use the gate for pedestrian traffic. Moreover, this could be useful in the situation where the driveway’s width is limited – a separate wicket is no longer indispensable in this case.

- Wicket with electrical strike – the factory-made electrical strike system increases the level of access control, enabling remote opening of the leaf using the intercom or an access card. Wickets equipped with an electrical strike have a modern, vertical handle.

- Gate and wicket widths are adjusted to Customers’ individual needs, within the dimensional ranges given in the technical specifications.

- Due to the specific configuration and dimensions of the filling as well as Customers’ requirements with regard to the aesthetic (facing of fillings in segments, gates, wickets), these products are manufactured solely with the standard heights given in the table of dimensions.

Color range

6 standard colors for no additional charge, any color from the RAL palette available upon request

ANY COLOR FROM RAL

RAL 7016 / ANTHRACITE

RAL 6005 / GREEN

RAL 9005 / BLACK

Technical sheet

Check out other products from the Supreme

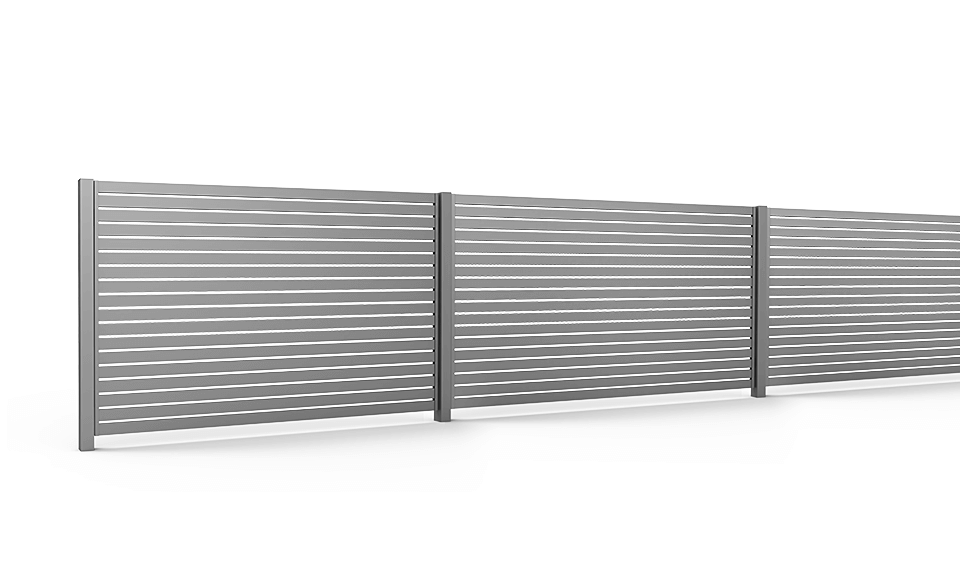

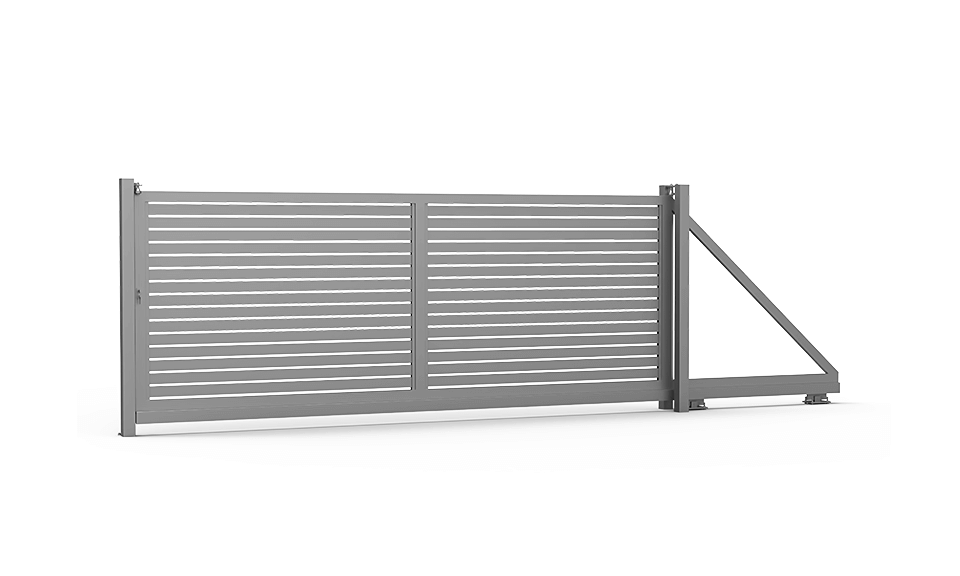

The presented double-leaf gates and wickets are part of the Infinity palisade fencing system, which also includes sliding gates with a self-bearing structure, as well as selded segments, posts and fasteners – all of these components form a visually consistent and technically well-thought-out ecosystem of products. Segments and sliding gates are manufactured in several standard height options, and their widths can be strictly adjusted to the Customer’s individual needs.

Tailor-made

Optimal adjustment to the Customer’s needs is achieved by manufacturing components to the desired dimension.

Automation

Option of built-in high-class automation with remote control.

No maintenance

Our products will not require maintenance for many years and will presence their excellent visual appearance.

Hot galvanization is the most effective and economical method of protecting steel against corrosion.

Individual elements of the fencing in its raw form (made of black steel) are delivered to a specialized plant – galvanizing shop. Before they are galvanized, they pass through a series of operations related to proper surface preparation: abrasive jet processing, degreasing, etching and fluxing through immersion in vats containing specific chemical substances. Next, products are sent to a liquid zinc bath with a temperature of 440-460 ° C where the diffusion process takes place – steel and zinc form a common alloy layer onto which a layer of pure zinc is deposited (during extraction of parts from the bath). This method of coating ensures thorough coverage of the product’s entire interior and exterior surface, including hard-to-reach places. The hot-dip zinc coating protects the steel against corrosion for many years. Assuming minimum mean thicknesses of obtained coatings within the range of 55-70 um (microns), we obtain anti-corrosion protection for a very long period of time, not requiring systematic maintenance, freeing the user from further, significant operational costs.

The combination of galvanized and powder-lacquered coatings – the DUPLEX system – ensures high resistance to corrosion.

Fences, gates and wickets – previously galvanized – are powder-painted using the electrostatic method using standard colors or any color from the RAL palette, according to the Customer’s individual needs. This process – with a rich palette of over 200 colors at our disposal – makes it possible to achieve the desired coloristic effect and aptly adapt the appearance of fencing to the environment and to the nature of the building being fenced off. Moreover, the combination of galvanization, surface preparation (in this case, Oxsilan®) and powder-lacquering technology – which professionals call the DUPLEX system – significantly increases the level of protection of steel products against corrosion, protecting the galvanized coating against natural oxidation of zinc as a result of weather factors. In turn, the application of high-quality powder paints at METPOL’s paint shop – meeting the requirements defined in the European QUALICOAT standard – as well as their very efficient and precise application by an automated unit of lacquering sprayers, translate to coatings with excellent functional and aesthetic properties.

The modern powder paint shop, with a properly designed surface preparation process, guarantees the highest quality.

Application of the lacquer coat takes place in METPOL’s modern, automated paint shop, where special emphasis is placed on the proper mechanical and chemical preparation of parts’ surfaces, which has a decisive impact on the durability and adhesion of the lacquer. For this purpose, METPOL introduced the innovative Oxsilan® technology – used at Mercedes Benz production plants, among others – in 2012. Oxsilan® technology not only ensures very high anti-corrosion resistance but also involves the use of chemicals friendly to the natural environment (consistently with the values METPOL holds dear). In the first stage, products pass through mechanical processing, then they are transported into the surface preparation tunnel for: degreasing washing, rinsing and silane application. Parts that have been cleaned and dried thoroughly reach the lacquering cabin, where automatic manipulators coat them with powder paint using the electrostatic method, with a min. thickness of 100 um. The final stage is holding products in a furnace at a temperature of 160 – 200 ° C (polymerization).