Palisade fencing

Ogrodzenia Przemysłowe Security

To najbardziej solidny model ogrodzenia przemysłowego, w którym ciężkie wypełnienie z profila 25×25 mm wspawane zostało w masywną, zamkniętą ramę. Brak poprzeczek poziomych oraz opcjonalne zwieńczenie górnej krawędzi zaostrzonym grzebieniem zniechęcają potencjalnych intruzów. Czynnikiem podnoszącym bezpieczeństwo może być także system mocowań, utrudniający demontaż za sprawą specjalnych akcesoriów i opatentowanych elementów złącznych. Dzięki zastosowaniu bardzo wydajnej technologii antykorozyjnej ogrodzenie przez wiele lat pozostanie bezobsługowe i zachowa imponujący wygląd. Palisada Security rekomendowana jest dla obiektów wymagających profesjonalnej ochrony zewnętrznej i kontroli dostępu (osiedla, szkoły, obiekty przemysłowe, rządowe, banki).

Typical width

2540 mm

filling profile

25 mm

post cross-section

80 x 80 mm

filling spacing*

105 mm

Table of dimensions

| Span height | Post length | Post cross-section | Number of fastenings |

| 1000 mm | 1600 mm | 60×60 / 80×80 mm | 4 pcs. |

| 1200 mm | 1800 mm | 60×60 / 80×80 mm | 4 pcs. |

| 1500 mm | 2100 mm | 60×60 / 80×80 mm | 4 pcs. |

| 1750 mm | 2400 mm | 60×60 / 80×80 mm | 4 pcs. |

| 2000 mm | 2600 mm | 60×60 / 80×80 mm | 4 pcs. |

Technical parameters

| Span width | Dimensions and spacing of filling |

|

Standard 2540 mm, other widths to size |

Per type according to table, other lengths to size |

| Cross-sections and spacing on post axes | Post lengths |

| 60×60 – 2610 mm, 80×80 – 2630 mm | Per type according to table, other lengths to size |

| Anti-corrosion coating | Optional equipment |

| Galvanization + powder lacquering | Prefabricated foundation in heights 20 / 25 / 30 cm |

Options

- Posts in the standard version are intended for embedding in the ground in monolithic, point foundations. Holes in the ground with a diameter of 25-30 cm are filled with concrete of min. class B-15 to a depth corresponding to the local frost penetration zone.

- We also make posts terminated by steel feet on custom order, enabling fastening of posts to a socle or other hard substrate.

- Spans may be delivered along with the fastenings appropriate for masonry posts (e.g. clinker brick, cloven blocks, etc.).

- A fence with a foundation requires the application of longer posts than the standard provided for a fence without a foundation, for which lengths have been given in the table of dimensions. The recommended length of posts for a fence with a foundation is equal to the total aboveground height of the fence + 60-70 cm for founding of posts on a monolithic foundation in the ground.

Color range

Ocynk ogniowy lub 6 kolorów standardowych bez dopłat, na życzenie dowolny kolor z palety RAL.

OCYNK OGNIOWY

ANY COLOR FROM RAL

RAL 7016 / ANTHRACITE

RAL 6005 / GREEN

RAL 9005 / BLACK

Technical sheet

Check out other products from the Security series

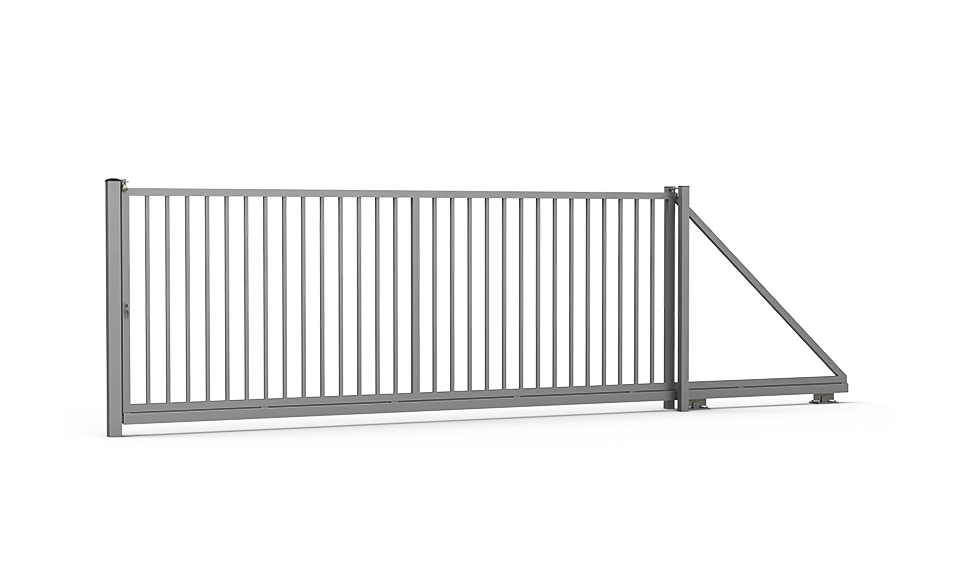

Leaf gates, sliding gates and wickets manufactured to the desired dimension and stylistically consistent with the fencing, with filling made using sections of the same dimensions and configuration as in fencing spans, are a natural supplement to our offer. A high quality prefabricated, reinforced foundation with a height of 20, 25, 30 cm, is an optional component of the system.

Spawane

The beautiful appearance is thanks to good industrial design and diligence in the production process.

No maintenance

Our products do not require maintenance for many years and keep their visual appearance.

System Duplex

The combination of galvanized and powder-lacquered coatings ensures high resistance to corrosion.

Hot galvanization is the most effective and economical method of protecting steel against corrosion.

Individual elements of the fencing in its raw form (made of black steel) are delivered to a specialized plant – galvanizing shop. Before they are galvanized, they pass through a series of operations related to proper surface preparation: abrasive jet processing, degreasing, etching and fluxing through immersion in vats containing specific chemical substances. Next, products are sent to a liquid zinc bath with a temperature of 440-460 ° C where the diffusion process takes place – steel and zinc form a common alloy layer onto which a layer of pure zinc is deposited (during extraction of parts from the bath). This method of coating ensures thorough coverage of the product’s entire interior and exterior surface, including hard-to-reach places. The hot-dip zinc coating protects the steel against corrosion for many years. Assuming minimum mean thicknesses of obtained coatings within the range of 55-70 um (microns), we obtain anti-corrosion protection for a very long period of time, not requiring systematic maintenance, freeing the user from further, significant operational costs.

The combination of galvanized and powder-lacquered coatings – the DUPLEX system – ensures high resistance to corrosion.

Fences, gates and wickets – previously galvanized – are powder-painted using the electrostatic method using standard colors or any color from the RAL palette, according to the Customer’s individual needs. This process – with a rich palette of over 200 colors at our disposal – makes it possible to achieve the desired coloristic effect and aptly adapt the appearance of fencing to the environment and to the nature of the building being fenced off. Moreover, the combination of galvanization, surface preparation (in this case, Oxsilan®) and powder-lacquering technology – which professionals call the DUPLEX system – significantly increases the level of protection of steel products against corrosion, protecting the galvanized coating against natural oxidation of zinc as a result of weather factors. In turn, the application of high-quality powder paints at METPOL’s paint shop – meeting the requirements defined in the European QUALICOAT standard – as well as their very efficient and precise application by an automated unit of lacquering sprayers, translate to coatings with excellent functional and aesthetic properties.

The modern powder paint shop, with a properly designed surface preparation process, guarantees the highest quality.

Application of the lacquer coat takes place in METPOL’s modern, automated paint shop, where special emphasis is placed on the proper mechanical and chemical preparation of parts’ surfaces, which has a decisive impact on the durability and adhesion of the lacquer. For this purpose, METPOL introduced the innovative Oxsilan® technology – used at Mercedes Benz production plants, among others – in 2012. Oxsilan® technology not only ensures very high anti-corrosion resistance but also involves the use of chemicals friendly to the natural environment (consistently with the values METPOL holds dear). In the first stage, products pass through mechanical processing, then they are transported into the surface preparation tunnel for: degreasing washing, rinsing and silane application. Parts that have been cleaned and dried thoroughly reach the lacquering cabin, where automatic manipulators coat them with powder paint using the electrostatic method, with a min. thickness of 100 um. The final stage is holding products in a furnace at a temperature of 160 – 200 ° C (polymerization).